With a case study of Tokisud-II OCP

Abstract - Demand of coal increasing day by day and to meet the demand evacuation of coal by means of open pit method is felt necessary to tune up the need. And introduction of state of art technology and increasing need of coal, open pit method has emerged as frontrunner among other modes of extraction. Due to this fact, pits are deepening more to most. Such deep pits in extreme climatic conditions, coupled with the trapping of pollutants due to air inversion, have presented a considerable challenge for the mining community in the area of open pit ventilation. Entrapment of pollutants in a deep open pit especially in winter could occur due to atmospheric inversion. In itself, this is not hazardous, but the diesel-engine earth-moving equipment used in the mine quickly renders the air within the pit severely contaminated, since the air inversion does not provide an outlet for these pollutants. The process of air inversion is complex and requires thorough understanding in order to design a mine ventilation plan to remove trapped pollutants in open-pit mines. The extraction and processing of minerals from open cast mines and quarries can produce significant fugitive emissions as a result of site activities such as blasting, unpaved road haulage, loading, primary crushing and stockpiling. This will ultimately affect adversely on the respiratory system of working people. The initial re-entrainment and subsequent dispersion of momentaneous dust presents a process complicated by the combination of the in-pit bench formation, the surrounding natural topography and the dynamic nature of emissions from these sites.

In general air inversion in deep opencast mines occurs in arctic or sub arctic area, where climate is cold. A study of open pit emissions on a newly planned open pit mine Tokisud-II within the Central Coalfield Limited command area was carried out based on available data from nearby mines. Studies carried out previously in other mines, utilizing atmospheric boundary layer (ABL) method. Conventional Gaussian based methods for far field dispersion carried out in other mines has also been studied here.

Typical operating emissions and meteorological conditions are obtained from the available data of Urimari EMP. Emissions are modeled using a Lagrangian framework within conventional atmospheric boundary layer (ABL) profiles expressed as functions of turbulence and velocity parameters under assumed neutral conditions.

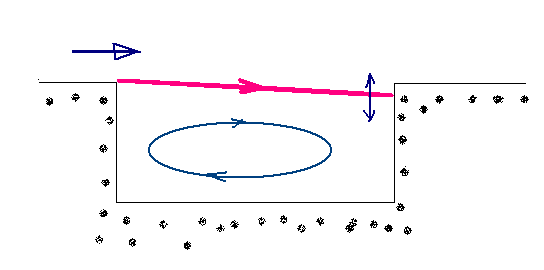

Atmospheric boundary layer while flowing through a deep open cast mine leaves different isolated zones, which separates the shear layers. These separation zones form expansion and compression zones. Due to variation of pressures the shear layers separates and reattached, which form a re-circulating cavity flow. A recompression region forms after reattachment point and flow forms a new uniform stream with a redeveloping zone. This ultimately developed fully at some distant downstream. A typical cavity flow is shown in Figure-1.

Fig:1: Application of ABL in a open pit (cavity)

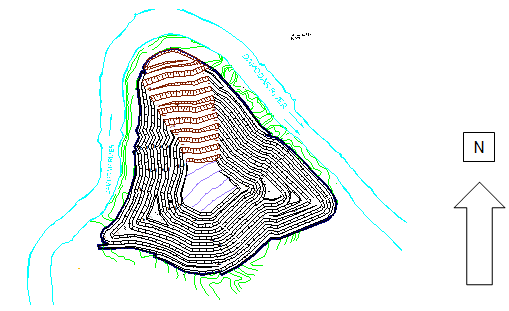

Introduction -Tokisud-II open pit mine unlike normal open cast coal mine has been designed in a constricted place circuited by an inverse U-shaped space of Damodar River. The nature of development of mine is also circuital similar to most deep open pit metal mines.

In the Tokisud-II mine, the bottommost seam considered for extraction does not incrop in the region. The mine reaches the floor at a depth of 65m. To overcome the difficulties to approach bottom most seam, all approach routes are made along the peripheral batter. The mine depth has become more as compared to its length and breadth. Therefore, as quarry becomes deeper and more productive, the potential to produce greater pollutant emissions including fugitive dust emissions will increase. The pit has been designed to minimize fugitive dust emissions, and to maximize the ventilation of the pit opening to dilute, disperse and remove fugitive dust from the workings. However, determination of the internal ventilation regime within the open pit is a complex process, as the driving natural wind system will change diurnally and seasonally in its intensity and direction, which are determined by the local wind systems and the differential heating of the surrounding surface by the sun.

The three dimensional velocity profile of the surface wind within the pit will follow principle of Atmospheric Boundary Layer (ABL). In addition, the meteorological conditions within the deep open pit coal mine are significantly affected by temperature (stability) and roughness (of the immediate surface) conditions which ultimately generate complex dispersion phenomenon including separation of atmospheric boundary layer, recirculation, re-suspension and settling of PM10 (SPM: < 10 µ).

The pattern of cavity flow (as shown in the Fig.1 above) depends upon the physical parameters of pit in addition to direction and velocity of flow of wind. In general cavity flows are classified in three types, i.e, open type, transitional type and close type.

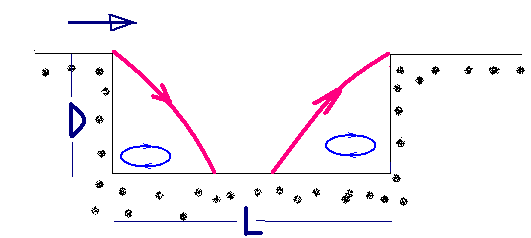

In open type ratio of length (L) to average depth (D)remains within 9. In this type of quarry, erratic deviation of flow pattern produces two distinct horizons. High pressure zone enters a little to the quarry, which creates a suction zone within pit. This forms vortex. In such case level of obnoxious gasses increases in the atmosphere and affects adversely on people working in bottom level.

Figure-2 OPEN TYPE

Figure-3 TRANSITIONAL TYPE

Figure-4 CLOSE TYPE

Transitional type cavity flow is noticed in those pits where, L/D ratio varies from 9 to 12. In this type of pit, high pressure zone (mean pressure coefficient Cp is positive) meets floor at the end i.e in the dip side leaving a wedge shaped suction zone below it. In such cases, main working front remains in high pressure zone.

Closed type cavity flow found in those pits where L/D ratio is more than 12. Atmospheric Boundary Layer (Cp positive) hits the floor and flows across the pit leaving two suction zones, one in rise side and another in the deep side. The sizes of these vortexes reduce with the increase of L/D ratio.

It may be concluded from the above, that as the depth of the open pit increases with respect to length, accumulation of obnoxious gases will be more. Thus the problem of ventilation will rise with increasing depth of the open cast mines.

Apart from this, mean pressure coefficient varies with direction of flow and width (W) and length (L) of the pit. More the ratio of W:L more will be zone of positive Cp within the pit. However, direction of flow also plays a major role here. If wind flows along the dip-rise direction (i.e., at zero degree with the dip-rise direction) of the quarry with W/L more than 1 and L/D greater than 2, Cp remains positive with increasing nature with the advancement of flow towards dip. However, if wind flows at 450 across the pit a wedge shape zone of negative Cp will be formed near the entry and it will be positive with increasing nature with the advancement of flow. This proves Cp varies proportionately with stream-wise advancement (x/L>+ve) (x is calculated from furthest crest along the direction of flow). Drag coefficient Cd shows an increasing nature as the direction of flow changes from zero to 900. However, Cd reduces from 60° to 90°.

Pollution transport in open cast mine under arctic inversion plays also a major role. Wind flow over the pit generates mechanical turbulence. Inversion adds to existing ventilation problems by suppressing thermal turbulence. In normal condition, atmospheric temperature decreases with height in the troposphere. But, in temperature inversion air temperature increases with height and cold dense air accumulates in bottom. In day time, due to solar radiation sensible heat flux warms the air near ground and it rises in convection current to the top of the ABL. These results a well mixed air in the ABL. However, in night, air immediate above ground cools down and convection current ceases. A stable but poorly mixed ABL is available.

Case Studies - Tokisud-II quarry has proposed to start from north and gradually deepened towards south. The length of the quarry along dip-rise and strike at surface is 1.6 km and 1.0 km respectively and 1.0 km and 0.4 km at floor respectively. Initial and final depths are 65 m and 340 m respectively. Width of the quarry in northern side is 400 m, whereas, in the south it is 1600 m. Average depth in the mid of the quarry is around 200 m. This quarry is found open type as L:D ratio is below 9. Thus this mine will have ventilation issues and mitigating measures needs to be searched from recent studies.

Damodar River has become circuitous here and passes from west to east in the north. Wind flow pattern and temperature are therefore different from other nearer places. Base line data generated within and around Tokisud village in summer are as:

| Month |

Wind Velocity (m/s) |

Predominant Wind

Direction (From) |

Temperature (° K) |

Cloud Cover (Oktas) |

| Min. |

Max. |

Avg. |

Min. |

Max. |

Avg. |

Lowest |

Highest |

| March |

0.5 |

2.6 |

1.18 |

NW |

293.3 |

314.4 |

302.6 |

0 |

1 |

|

< 0.5 |

1.7 |

0.72 |

S |

293 |

313.2 |

301.9 |

0 |

0 |

|

< 0.5 |

2.5 |

1.08 |

NW |

294.8 |

314 |

303.1 |

0 |

1 |

| April |

< 0.5 |

3.2 |

1.16 |

NW |

295 |

314 |

304.3 |

0 |

0 |

|

< 0.5 |

3.2 |

1.39 |

W |

294.9 |

315.2 |

305.5 |

0 |

0 |

|

< 0.5 |

2.6 |

1.04 |

S |

295.9 |

315.7 |

306.6 |

0 |

0 |

|

< 0.5 |

2.7 |

1.14 |

SE |

295 |

316.1 |

305.1 |

0 |

1 |

| May |

< 0.5 |

3.6 |

1.25 |

SW |

298.6 |

312.2 |

305.1 |

0 |

2 |

|

< 0.5 |

3.2 |

1.18 |

NW |

297.3 |

311.8 |

304.5 |

0 |

0 |

|

< 0.5 |

2.9 |

1.1 |

S |

299.1 |

310.4 |

304 |

0 |

1 |

|

< 0.5 |

2.9 |

1.15 |

W |

298.2 |

312.1 |

305.2 |

1 |

3 |

|

< 0.5 |

3.4 |

1.39 |

N |

297.6 |

313 |

305 |

0 |

0 |

| June |

< 0.5 |

3.1 |

1 |

NW |

299.1 |

314.8 |

306.2 |

0 |

1 |

|

< 0.5 |

3.3 |

1.2 |

SE |

299.6 |

314.5 |

307.8 |

0 |

0 |

|

< 0.5 |

3.1 |

1.13 |

NW |

301.5 |

313.6 |

306.8 |

0 |

1 |

|

< 0.5 |

3.1 |

1.63 |

SW |

299.9 |

313.8 |

306 |

0 |

0 |

|

< 0.5 |

2.9 |

1.43 |

SE |

298.7 |

314.3 |

295.2 |

0 |

0 |

|

< 0.5 |

2.8 |

1.18 |

S |

296.3 |

314.9 |

305.7 |

0 |

1 |

It has been observed that wind flows over this area mostly from NW and SW and occasionally it flows from south to north. If wind enters from south the flow direction will become zero and it will leave less zone of negative Cp 5i.e minimum suction zone. However, in such case, wind velocity should be more than 3m/sec with clear sky. In summer, pollutants with gasses below mine will go up due to inversion and driving out process for obnoxious gasses will be better. However, in night accumulation will be more due to absence of arctic inversion.

A comparatively worse result will come if wind flows from SW to NE i.e at 450.In such case a major suction zone (negative Cp) will be created in the dip side.

As the mine is unlike other normal coal mine and depth is rather high as compared to other running mine turbulent mixing and local eddies will be formed within the pit after blasting.

TOKISUD-II Opencast Mine

Conclusion - It is obvious that air velocity, air temperature, diffusivity coefficient and slope angle are important controlling parameters in the inversion process. The flow regime should be laminar at the origin, but as the flow progresses toward the center of the pit it may change to quasi-laminar and generate local eddies towards the pit bottom. The total energy of the resulting quasi-laminar flow as well as the small local eddies will not be enough to lift the inversion cap. However, a combination of quasi-turbulent flow and the local eddy transport will result in removal of some of the pollutant mass from the pit bottom, either due to turbulent mixing, or due to advection. Presence of back-flow may appear to be a logical mode of flow in deep open-pit mines during cold.